Tubes Departement

Thanks to the use of new CNC machinery with high technological content, we are able to process pipes of any material (aluminum - copper - brass - iron - stainless steel. Etc.) and profiles (thud - square - rectangle etc.).

Starting from cut pipe or directly from 6 m long bars, we are able to perform bending, deformation, trimming, assembly and welding operations.

Having experienced technical personnel, supported by new generation bending machines, and a special department for the construction of the tooling, in recent years our attention has turned to the processing of stainless-steel pipes with a thickness from 0.2 mm to 0.8 mm even with very narrow radii of curvature and the creation of prototypes according to the customer's studies.

All our products are tested inside the metrology room through the use of a laser measuring table, 3D scanning arm and digital profile projector.

In the assembly and welding department, using various torch brazing stations, tig welding and a robotic cell for wire welding, the assemblies are prepared for any external surface treatments in order to guarantee our Customers a finished product, whose production process has been carefully followed from the first cut to the final delivery.

ADIGE TC 720 AUTOMATIC HYDRAULIC CNC SAW

Cutting capacity mm Round tube 8-80; square tube 10x10 - 70x70

Rectangular tube 15x10 - 80x70 full 12-30

Automatic brushing for cuts from 150 to 3000 mm

EKORD 65 CNC-D BEMA BENDING MACHINE

N ° 3 electric axes

Left or right bending

Pipe bending up to ø 63.5 x 3

E-TURN 35 BLM TUBE BENDING MACHINE

Fully electric machine (12 electric axes)

Right and / or left bending within the same bending cycle.

Possibility to mount up to 6 different bending radii simultaneously and push bending

Integrated pallet system

Pipe bending up to ø 35 x 2

TUBE BENDING MACHINE DYNAM 0 MR200 BLM

Left or right bending

Possibility to mount up to 4 different radii of curvature simultaneously

Integrated pallet system

Pipe bending up to ø 25.4 x 2.5

ELECTRIC PIPE BENDER CRIPPA 955LE

reconfigurable right or left direction of bending

Maximum diameter up to Ø 55x2.5 mm

9 Axis CNC

ELECTRIC PIPE BENDER CRIPPA 942LE

reconfigurable right or left direction of bending

Maximum diameter up to Ø 42x2mm

9 Axis CNC

REVERSE CN 35 DS BEMA TUBE BENDING MACHINE

N ° 5 electric axes

Right and / or left bending within the same bending cycle.

Possibility to mount up to 6 different bending radii simultaneously and push bending

Integrated palletizing system

Pipe bending up to ø 35 x 2

REKORD 35 FCZ DS BEMA TUBE BENDING MACHINE

N ° 4 electric axes

Possibility to mount up to 4 different radii of bending simultaneously

Pipe bending up to ø 35 x 2

TUBE BENDING MACHINE542 CRIPPA WITH MAGAZINE

Hydraulics (n. 5 electric axes)

Right and/or left curvature within same bending cycle.

Possibility to mount up to 6 different radii of curvature simultaneously and push curvature

Integrated loading and unloading system Pipe bending up to 42 x 2

TAPPING MACHINE SER 15X6 CN UNIVERSAL BEMA

Max work force 15 T

Max tube capacity ø 114

Possibility of carrying out 6 deformation steps within the same work cycle

Fully electric machine

Work diameter 4 mm - 50 mm

No. 6 processing steps of the vice punch

Thrust force 8 T.

Clamping force 12 T.

Integrated palletizing systems

ELECTRIC TUBE SHAPING MACHINE S2086E CRIPPA

Machinable diameter 4 mm - 42mm

6 processing steps including 3 CNC-controlled axes

Thrust force 8T.

Locking force 12T.

Integrated palletizing systems

CRIPPA PO16 TUBE SHAPING MACHINE

Machinable diameter 4 mm - 32mm

4 processing steps

Thrust force 16 T.

Locking force 20T.

Integrated palletizing systems

THREE-DIMENSIONAL LASER MEASURING TABLE MOD. LABES 3 BEMA

Probe CAM 2 scanning Laser Line

Probe V3 FaroArm Fusion 8 ft.

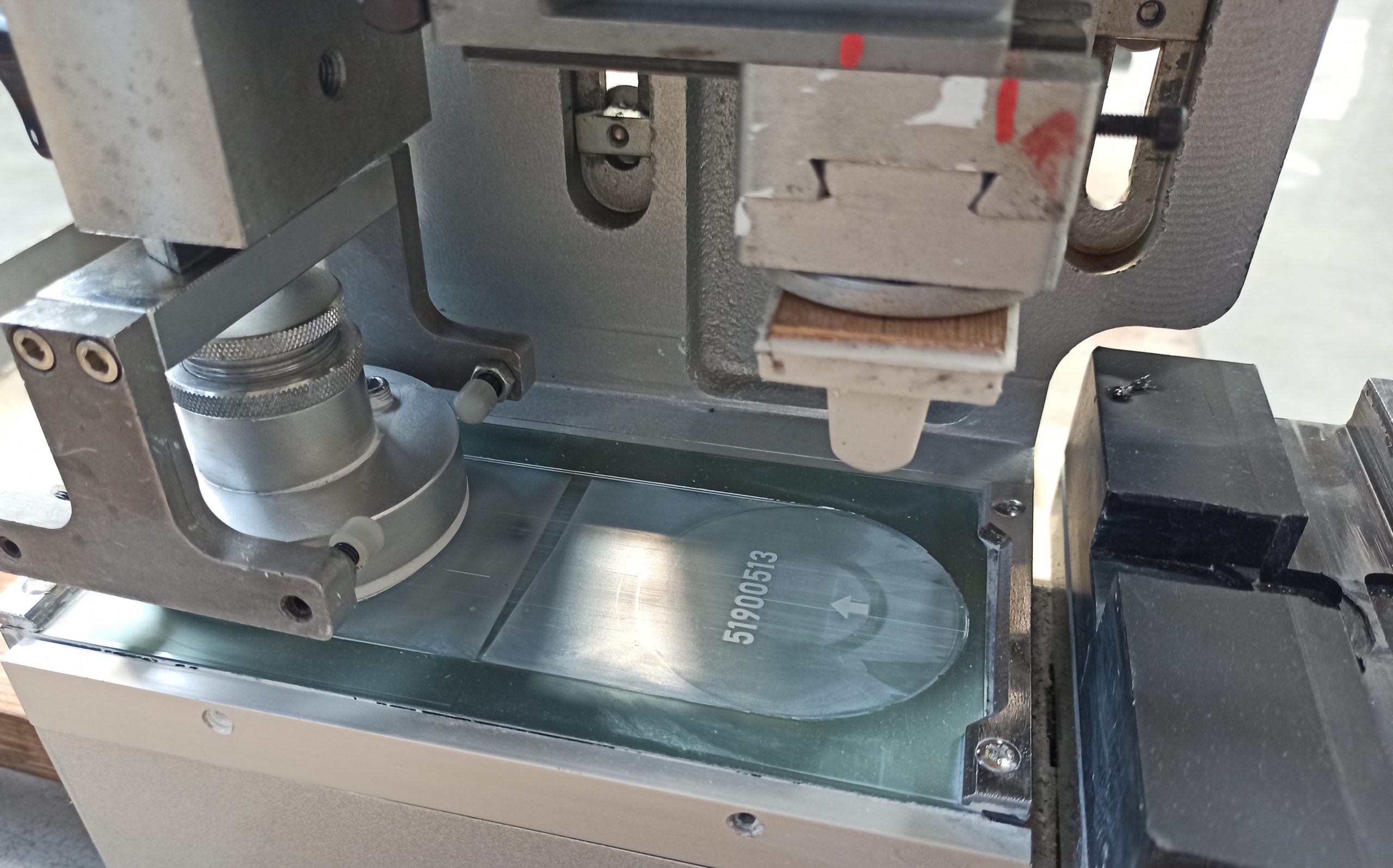

EASYGAUGE CRIPPA PROJECTOR

Easygauge is an extremely versatile dimensional measuring device that allows contactless measurement of profiles with a repeatability of 5µm.

MITUTOYO PROFILE PROJECTOR

PH-A14 XY = 203 x 102 mm

Geometric processing unit

QM DATA 200

LAVAMETAL

Industrial washing machines in stainless steel

Wash

Flushing

Drying

MANUAL PAD SYSTEM

Design, customization of prints

Clichè engraving

on any material

MICRO-POINT MARKING SYSTEM

Our offices are at your complete disposal for technical analyses, estimates and any planning.